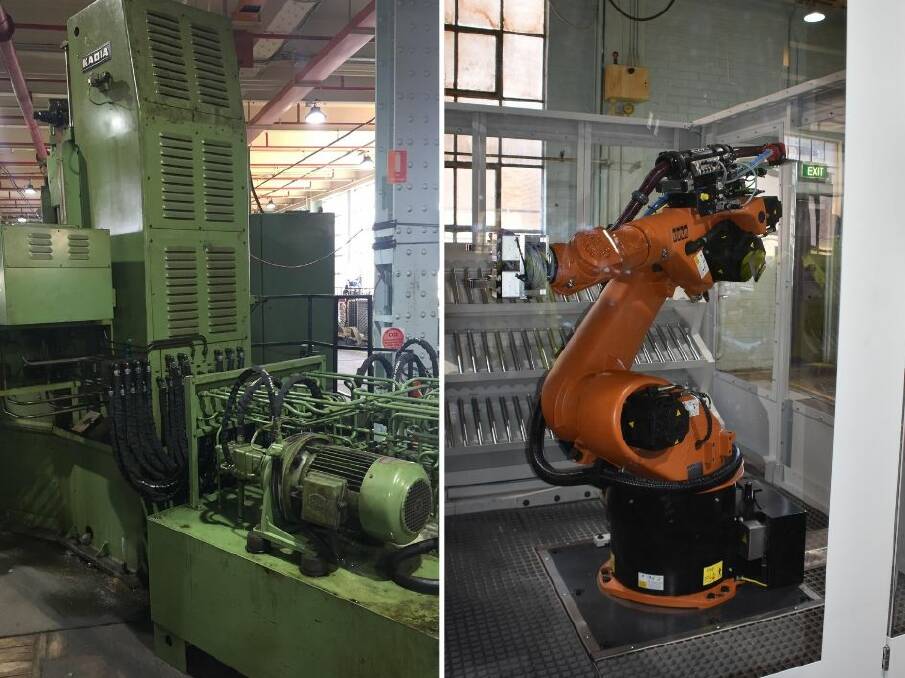

It has come all the way from Germany, it's one of three in the world and is the first to be commissioned, right here in Lithgow.

Subscribe now for unlimited access.

$0/

(min cost $0)

or signup to continue reading

Thales Australia unveiled a $1.8 million honing machine on Wednesday, July 24 at the Lithgow Arms factory.

The brand new machine is now activated on the production line and brings Thales Australia's investment to more than $30 million in plant and equipment at the Lithgow factory since 2006.

Member for Bathurst Paul Toole officially unveiled and activated the new machine along with Thales Soldier Weapons Systems director Graham Evenden.

The machine will essentially produce a mirror finish inside of a barrel before it's rifled, according to Mr Evenden.

"It's a polishing process, it polishes the inside of the barrel before it's rifled and once it's rifled, the bullet travels up the barrel then the rifling spins the bullet and that's what makes it accurate on it's way towards the target," he said.

He said it was a major investment for the factory and an important one.

"One of the key reasons we've invested in this particular honing machine is because not only does it allow us to make barrels quicker, but most importantly it allows us to make new products," he said.

The barrels manufactured in the new honing machine were now longer than they were in the old system, which had been in operation for 38 years at the Lithgow Arms, according to Mr Evenden. He said it contributed to making top quality barrels.

"[The honing machine] increases productivity so it hones the barrel four times faster, it allows us to make new products and the quality is a step ahead of the old one, which is important as we head into the export market," he said.

Currently in the commercial firearm space, Lithgow Arms exports to eight countries around the world.

"This new honing machine will make us more competitive in the global market, it allows us to ensure that we're investing in the sovereign industrial capability here. We're getting ready for the future," Mr Evenden said.

He said the device was manufactured by the German company KADIA, which was the only company globally that made honing machines like the one at Lithgow Arms.

"We are the first one to be commissioned, so we are leading the way in the world on improved honing to produce better barrels," he said.

Mr Evenden said it had been an 18 month process to get the machine into action.

"Once we were happy with it in Germany, it was pulled apart, put in containers and shipped to Australia then very quickly followed by a German commissioning team from Kadia, who built and commissioned the machine to the satisfaction of mechanical engineering," he said.

He said the 18 tonne machine also sat on top of a two metre deep concrete pad.

"Because of the vertical movement there's even more strain on the ground so that's why there's two metres of concrete there which was an adventure digging that hole and filling it," he said.

Member for Bathurst Paul Toole said the honing machine was a fantastic opportunity for the Lithgow area.

"This device is so important because it improves the barrels for the rifles that we're going to see developed and produced right here in Lithgow.

"It's some great technology and it's a credit to everyone who has been involved in the production of this new line and investment.

"There over a hundred of years of history in this area and here is Thales today going from strength to strength," he said.